Flagship Project: Biomass Introduction

- Home

- CEFIA Flagship Projects

- FP-Biomass

Purpose of Biomass Flagship Project

Biomass energy refers to renewable energy derived from biological resources such as plants, animals, and other living organisms and municipal wastes. Biomass has come to be re-emerging while countries are trying hard to go their respective transition pathways, for the features such as renewable nature, geographical diversity and availability.

The CEFIA Biomass Flagship Project (“the Project”) currently focuses on agricultural biomass that are sourced from agricultural plants. Forest biomass utilization by plantation and replantation with minimal impact on the original ecosystem is being considered as well.

(1) Dedicated CFB biomass power plant

Countries in Asia have been trying to utilize biomass, inherently carbon-neutral, for power generation for cleaner and sustainable electricity supply, reduced wastes, and local development, which ultimately will bring them to a circular economy in the future.

For dedicated biomass power generation from agricultural biomass to municipal wastes, CFB (circulating fluidized bed) boiler has become a potential option.

| A CFB (circulating fluidized bed) boiler, as well known, is suitable to both dedicated biomass power generation with quite a wide range of biomasses and wastes and co-firing of coal with biomass. CFB can be flexible about the choice of biomasses-such as wood chips/pellets, palm kernel shells (PKS), etc., leading to their widespread adoption by Japanese industries.

<Key technical features>

|

(2) Co-firing of biomass at existing coal fired power plants

In Asia, where many countries have embarked on their respective energy transition journeys while coal as a reliable generation source remaining in their energy mix, co-firing of biomass at existing coal fired power plants is emerging initiated by governments.

| Malaysia’s TNB made a success in biomass co-firing by 1% and has proceeded to 2% demonstration. Indonesia has identified 47 power plants for co-firing of coal and biomass. In 2025 the above is to reach 52 with over 100 units in all Indonesia, utilizing woody and agricultural biomass. Key challenges for biomass are (i) ensuring of required amount and availability of feedstock; and (ii) cost/commercial consideration to balance between energy affordability, security and sustainability. <Points of consideration>

|

| Shown at the left top is a near-future image by PLN of a locally-initiated large scale co-firing power plant complex with a broad range of biomass resources. ASEAN is rich in biomass resources (coconut shells, rice husks, wood residues, etc.), which the company believes is to make co-firing highly conducive to energy transition in terms of sustainable value chain and environmental compliance. |

(3) Biomass Pellets and Briquettes

While being environmentally-friendly and carbon-neutral by nature, biomass just as it is, is not really suitable for use as fuel due to its characteristics such as low bulk density, etc. Accordingly, densification by pelletizing or briquetting is common before utilization of biomass as fuel. Since the properties of biomass pellets or briquettes affect handling convenience, many types of technologies have been developed in pursuit of efficiency and better economy, and most of them are commercially established.

Biomass briquettes are compacted blocks made by applying pressure to raw biomass. Typically measuring 50–100 mm, they require minimal processing and a higher moisture tolerance (15–20%). This allows production to be simpler, more cost-effective and a wider choice of the raw material conditions—one of the clearest biomass briquettes benefits.

Biomass pellets, on the other hand, are small, cylindrical fuel pieces made from extremely dry (7–10% moisture) biomass that is pulverized, compressed, and extruded (6–12 mm diameter). Their uniformity enables precision burns and easy feeding—key in automated combustion systems—highlighting the importance of biomass pellet production for scale industries.

Black pellets are decarbonized fuels with a quality similar to coal produced by heating biomass at a certain time at 200-320 degrees Celsius.

Compared to conventional white pellets without such carbonization process, it has a higher calorific value, water resistance and better grindability in fine mills, and can be used in almost the same way as coal by utilizing existing coal infrastructure.

Whether to go for black pellets or white pellets depends on requirements such as choice of biomass and its cost as well as production scale.

a. Briquette production by Grind Mill

| Grind Mill is a solid fuel production machine designed to convert biomass—primarily rice husks—into three kinds of solid fuels suitable for dedicated combustion or co-firing with coal; “Momigalite” that is hollow and stick-shaped solid fuel, curl chip, and crushed rice husks. By producing stable and uniform fuels from rice husks, rice straws, and wood residues, Grind Mill enables higher biomass substitution ratios in coal-fired boilers, significantly contributing to CO₂ reduction. This technology has been widely adopted by users seeking fuel flexibility and practical pathways to decarbonization. <Key technical features>

|

b. Black pellet production

| In Gia Lai Province, Vietnam, Idemitsu Kosan has constructed a biomass black pellet production plant, after years of research activities. Their research outcomes indicate the following points, which prove the produced black-pellets are of high, export quality:

The black pellet plant with production capacity of 120,000 ton per year is owned and operated by Idemitsu Green Energy Vietnam. |

4. BECCS (Bioenergy with Carbon dioxide Capture and Storage)

Compared to valuable renewable energy (VRE) such as solar and wind, biomass is relatively stable in supply and can provide flexibility in the case of on-grid power plants. Though seasonality is observed with most types of biomass, it can be handled through appropriate storage and stocks management as well as sustainable sourcing of the fuel.

In the same context, biomass power as part of a hybrid power plant with VRE, can play a role of non-intermittent electricity supply enabling such a plant to achieve efficient power supply, which gives countries a great option for implementation until the time affordable energy storage in volume comes to be in place.

Biomass as carbon-neutral fuel can even be carbon-negative if combined with carbon capture and storage (CCS), which is called BECCS in abbreviation.

| Toshiba Energy Systems & Solutions Corporation (Toshiba ESS) has installed and begun operation of a large-scale carbon capture and storage (CCS) demonstration facility at the Mikawa Power Plant in Omuta City, Fukuoka Prefecture, a 50 MW biomass power plant fueled on palm kernel shells (PKS) operated by Sigma Power Ariake. As the world's first large-scale BECCS compatible facility, it is expected to become a carbon-negative power plant. Prior to the above development, Toshiba ESS started operation of a 10 ton-per-day capacity pilot plant on the plant's premises in 2009 in pursuit of scale-up for further implementation. The plant in operation captures CO2 more than 500 ton/day, which is equivalent to 50% of daily emissions. The demonstration was carried out as part of “Sustainable CCS Project” that has been commissioned by Ministry of the Environment, Government of Japan (MOEJ) that is to continue until 2030 when verification of the process from capture, storage to monitoring is completed. |

(5) Biochar-traditional yet emerging substance and production systems

The other biomass utilization emerging and getting incomparable attention is biochar production and application. Biochar is a solid material made by heating biomass at temperatures above 350°C under controlled oxygen concentrations that do not cause combustion. Biochar, as one of the carbonous materials, is produced through biomass pyrolysis under inert condition. Biochar application to agricultural land have effects such as improving soil permeability, water retention, and breathability, and it has been designated as a soil improvement material in Japan, and many countries have begun the same in pursuit of soil enhancement that brings in increased harvest of better quality. Biochar provides immense benefits in terms of agricultural sustainability and productivity improvement and of CO2 emission reduction benefiting from the inherent properties to absorb and store CO2 underground for a long period of time.

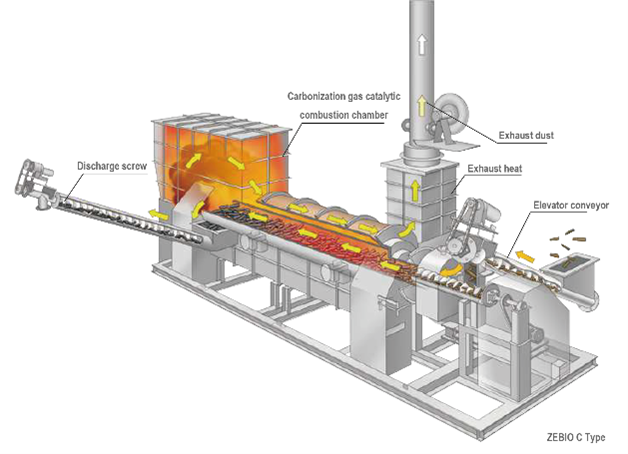

a. Continuous-type Biochar Production System

| This system employs a screw-based continuous carbonization process. It is particularly suitable for small biomass materials such as rice husks, chopped rice straw, and peanut shells. The system allows flexible adjustment of biochar quality by controlling carbonization time and temperature, making it ideal for applications requiring stable and customized biochar properties. <Key Technical Features> -Compatible with a wide range of raw materials -Operational flexibility: Continuous or batch-type systems can be selected according to user requirements, energy availability, and scale of operation. -Energy efficiency: The continuous-type system consumes minimal electricity and uses a self-combustion carbonization method, in which the heat required for carbonization is primarily provided by burning the volatile gases of the raw material itself, optimizing the LCA of biochar production. -Quality control: The continuous-type system allows precise adjustment of carbonization conditions to produce biochar with tailored physical and chemical characteristics. |

| This is another continuous-type decarbonization machine that will be introduced under the NEDO Biochar Demonstration Project that is introduced in the following technical overview. -Designed for energy efficiency throughout the life cycle, such as that the machine recovers gases generated in the carbonization process for reutilization as a heat source. -Combination with optional equipment enables to build a generation system with biomass energy as alternative to fossil fuels -Suitable for high-moisture material like processing of paper sludge and other sludges, in addition to standard agricultural biomasses. |

b. Continuous-type Biochar Production System

| This batch-type system enables biochar production without the need for electricity. It does not require raw material size uniformity, allowing for the carbonization of larger feedstocks such as bark and coconut shells. Moreover, feedstocks with high moisture content can be processed directly without prior drying, providing a cost-effective and robust solution for decentralized biochar production.

<Key Technical Features> -Versatility of feedstocks: Capable of processing a wide variety of biomass, from fine rice husks to large coconut shells. -Operational flexibility: Continuous or batch-type systems can be selected according to user requirements, energy availability, and scale of operation. -Energy efficiency: The brick-type system operates without electricity, reducing operating costs and enabling deployment in off-grid areas. |

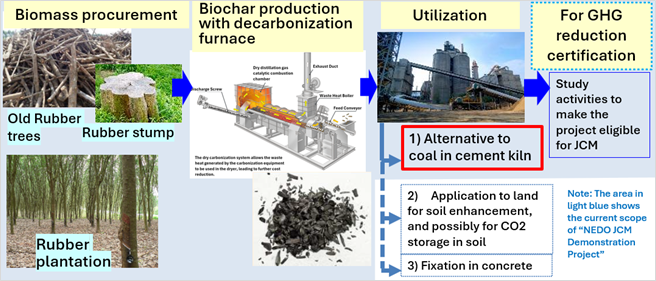

In addition, Biochar can serve as an alternative fuel source for decarbonization that is central to the Joint Crediting Mechanism (JCM) Demonstration Design Study on Biochar Production and Utilization in Thailand (the Study) as introduced below.

[Technical Overview of NEDO Biochar Demonstration Project]

JCOAL team, in close collaboration with a Thai cement company and supported by relevant institutions of both Japan and Thailand, has been engaging in a biochar project that is in the FEED stage in JFY 2025 (August 2025-July 2026).

It is common in Japan and many other countries that cement kilns use industrial waste as fuel. Normally, coal is used in the cement kiln that operates at quite high temperature compared to calciner, which is the case with the Project.

As such, biochar will alter coal so that steady reduction of CO2 emissions is expected.

Overview of the NEDO Biochar Demonstration Project

Introduction of Lead Organization

Japan Carbon Frontier Organization (JCOAL) is the lead organization of the biomass flagship project. For the past decade, JCOAL has been engaging in researches and studies as well as knowledge and technology sharing on biomass cofiring and dedicated firing in collaboration with its counterparts in ASEAN, outcomes of which would have been conducive to relevant policy formulation and implementation facilitation. By widening the scope to other biomass utilization taking the opportunity of engaging in the ongoing NEDO project, JCOAL wishes to work further with regional stakeholders involving Japanese partner companies with their unique technologies.

JCOAL is determined to contribute to formulate sustainable biomass energy projects that are tailored to diverse conditions of AMS while considering of the possibility of regional/cross-border value chain formulation, which it hopes will constitute a significant piece of cleaner energy and energy transition landscape in ASEAN.

HP (日本語): 一般財団法人カーボンフロンティア機構

HP (English): JAPAN CARBON FRONTIER ORGANIZATION|一般財団法人カーボンフロンティア機構

Activities

-

JCOAL, in collaboration with relevant institutions, participated in research activities to produce the following reports, prior to its participation as a flagship organization in CEFIA.

- ASEAN Readiness for CCT and CCU Technologies Towards Carbon Neutrality

- Study on the Applicability of CCT for a Comprehensive and Optimal Carbon-neutral Solution in ASEAN

- The New Role of Coal Fired Power Plant in the Era of Energy Transition (SR)

- Study on Enhanced Flexibilisation of Coal-fired Power Plants for Optimal Grid Stabilisation in the ASEAN Region

- Study on the Biomass and Coal Co-Combustion in the ASEAN Region

https://www.eria.org/publications/study-on-the-biomass-and-coal-co-combustion-in-the-asean-region/

- Biomass and Coal Co-combustions in the ASEAN Region (Phase 2)

https://www.eria.org/publications/biomass-and-coal-co-combustions-in-the-asean-region-phase-2/

- ASEAN CCT Handbook for Power Plant (Ver. 2)